ScanX Series

The ScanX-systems are high precision volumetric bulk material measurement systems for road trucks or mining trucks. With ScanX-, the truck bed is planted centrally underneath the sensor. With the truck at standstill, an accurate measurement is made. The laser scanners are installed above the driveway. The ScanX- uses a 2D sensor and with its motion, generates a 3D profile of the loading area when the truck is at standstill.

In measuring systems, it is necessary to do measurements in loaded and unloaded conditions. Both profiles are saved and then the calculations are performed, whereby the empty 3D profile is deducted from the full 3D profile. The difference between the two volumes gives the volume of the transported bulk material. The product is available as a kit, containing a basic kit with the sensors, cable set and the evaluation unit including power supply (in a control cabinet). In addition, there are extra modules that can be optionally included. Module identification (number plate) With this module an ANPR camera (Automatic Number Plate Recognition) is installed next to the driveway at the height of the number plates, from where the vehicle identity is recorded in the driveway or in the passageway.

The sensors are attached to a portal or a pillar with a jib, at a height of approx. 7 m. When the truck enters the measuring area, the 3D profile measurement is done. This takes about 1 min. The measurement is always made in two steps: an empty 3D profile measurement and a full 3D profile measurement. The difference of these two gives the volume of the bulk material. Several measuring stations can also work in combination. In this case, there is a full and empty measurement at different locations. It is also possible to save the empty profiles alone of a vehicle and the loaded measurement can be taken afterwards. The browser- based commissioning tool enables commissioning and error analysis at the measuring station via a handheld device (mobile phone, tablet – connected via Wifi.

STANDARD FEATURES

TECHNICAL DATA

- Laser scanner

- Laser scanner type

- Measurement Procedure

- Material

- Accuracy

- Measuring time

- Interface

- Temperature

- Supply

- 1 or 2

- At a standstill

- Bulk material 98+%

- Ethernet TCP/IP

- -25 °C +50°C 230 VAC

- Depending on the length of loading body

- 2D Laser scanner

- Truck in the measuring area

- Sand, soil, gravel, stones

- Depending on the quantity and area size

- Other interfaces customer-specific Other temperature ranges on request

SERVICE

OTHER SERVICES

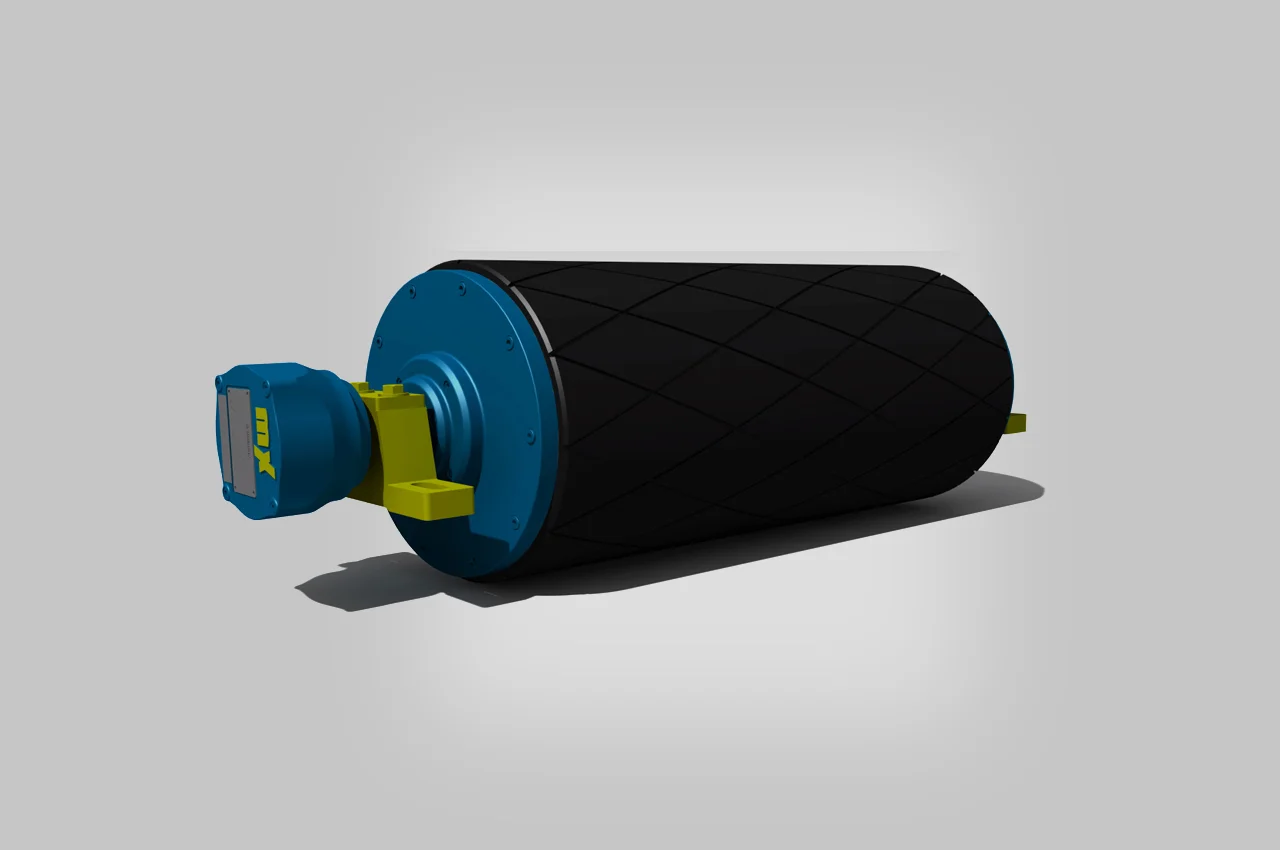

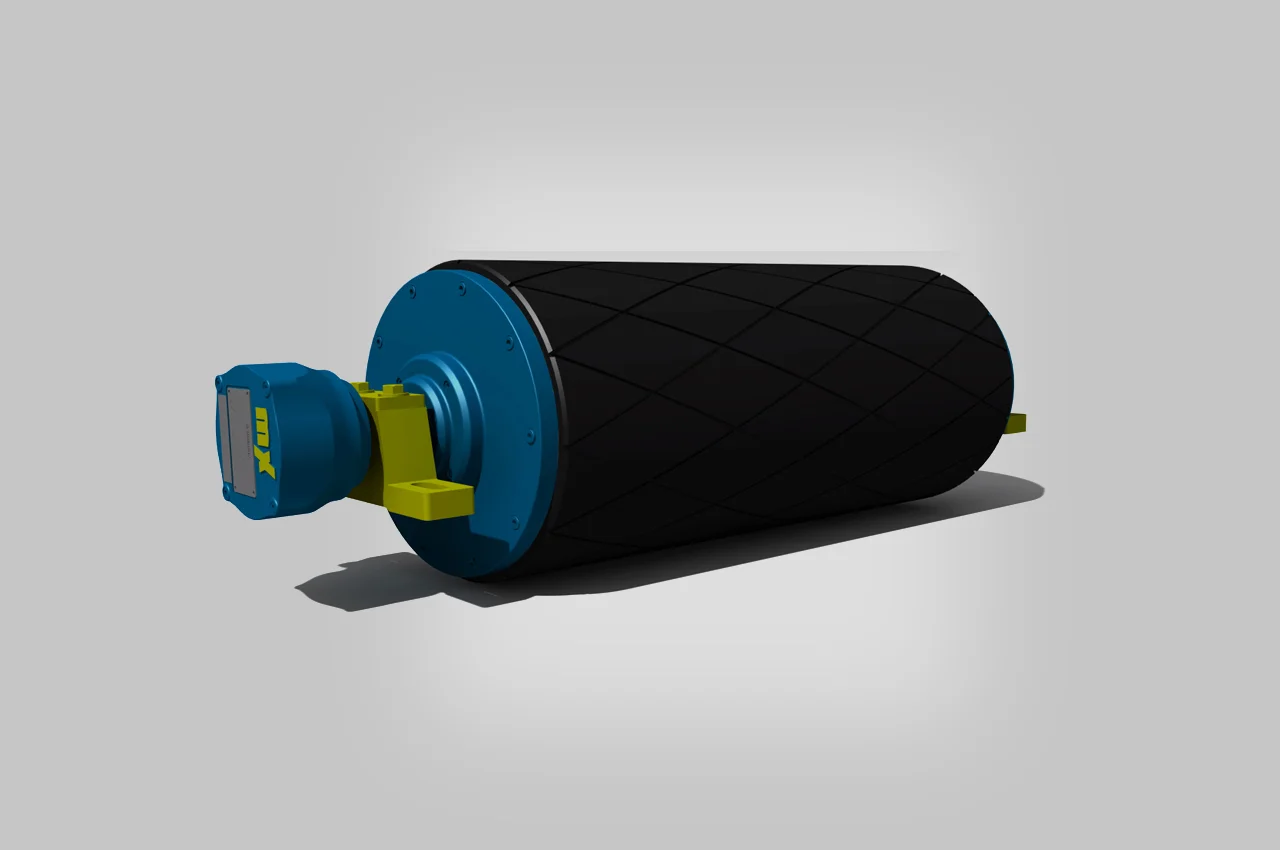

Drum Motors ED series

SHX series slurry pump