CYX Series Hydrocyclones

YX series hydrocyclones stand for the future generation of hydrocyclones. Innovative features paired with cutting edge technology make the new range a superior product in its category. CYX series hydrocyclones are structured to fulfill diverse purposes in mineral and sand processing coupled with overall plant performance.

FEATURES

Inlet Head Design

The innovative CYX series Hydrocyclone’s inlet design ensures finer and sharper particle separation at high capacities.

The outer wall spiral design entrance pre-classifies the feed solids before entering the main body of the cyclone. The

improved vortex in the inlet head of the CYX series reduces misplacement of material to the overflow and generates

extended wear life.

Exceptional Separation Efficiency

The CYX series hydrocyclones guarantee accurate and efficient separation of particles by size (mass). The wear resistance

linings in the feed distributor minimizes the turbulence, thus improving the separation efficiency.

Diverse Applications

CYX series hydrocyclones are suitable for various applications and fulfill diverse needs. The typical application includes

size classification, dewatering, washing application. The broader product range of hydrocyclone sizes brings improved

efficiency and profitability. Each model from CYX series hydrocyclones offering features a range of vortex finder and apex

inserts to fine-tune wet classification performance.

Increase Uptime

The futuristic design of the CYX series hydrocyclones ensures maximum uptime paired with lower operational costs. The

CYX series hydrocyclone’s industry-leading flow rate creates an optimal flow even with the required pressure drop. The

incorporated wear resistance liners ensure increased uptime and a better long-life cycle for the overall parts involved.

APPLICATIONS

- Size Classification

- Dewatering

- Aggregate Processing

- Sand Processing

- Plastic Recycling

KEY BENEFITS

SERVICE

OTHER SERVICES

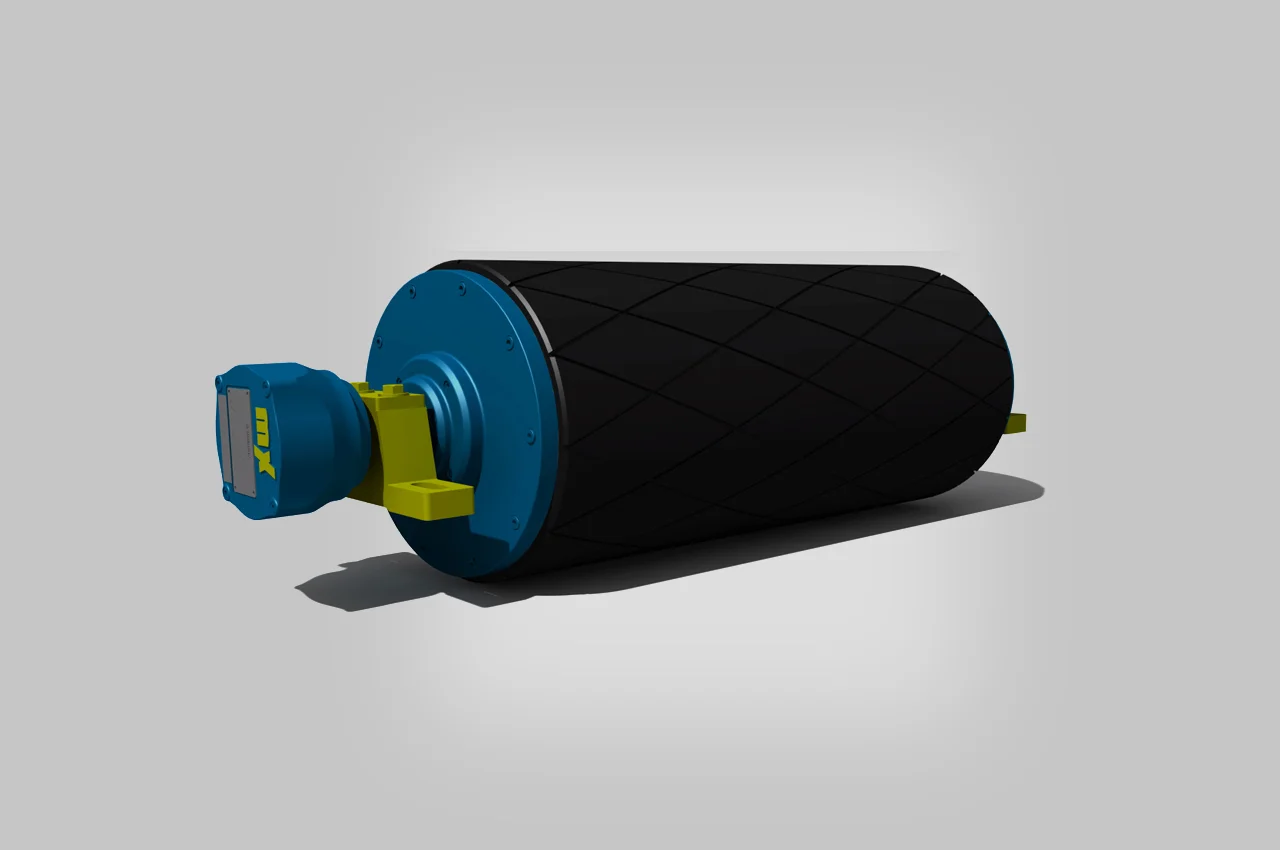

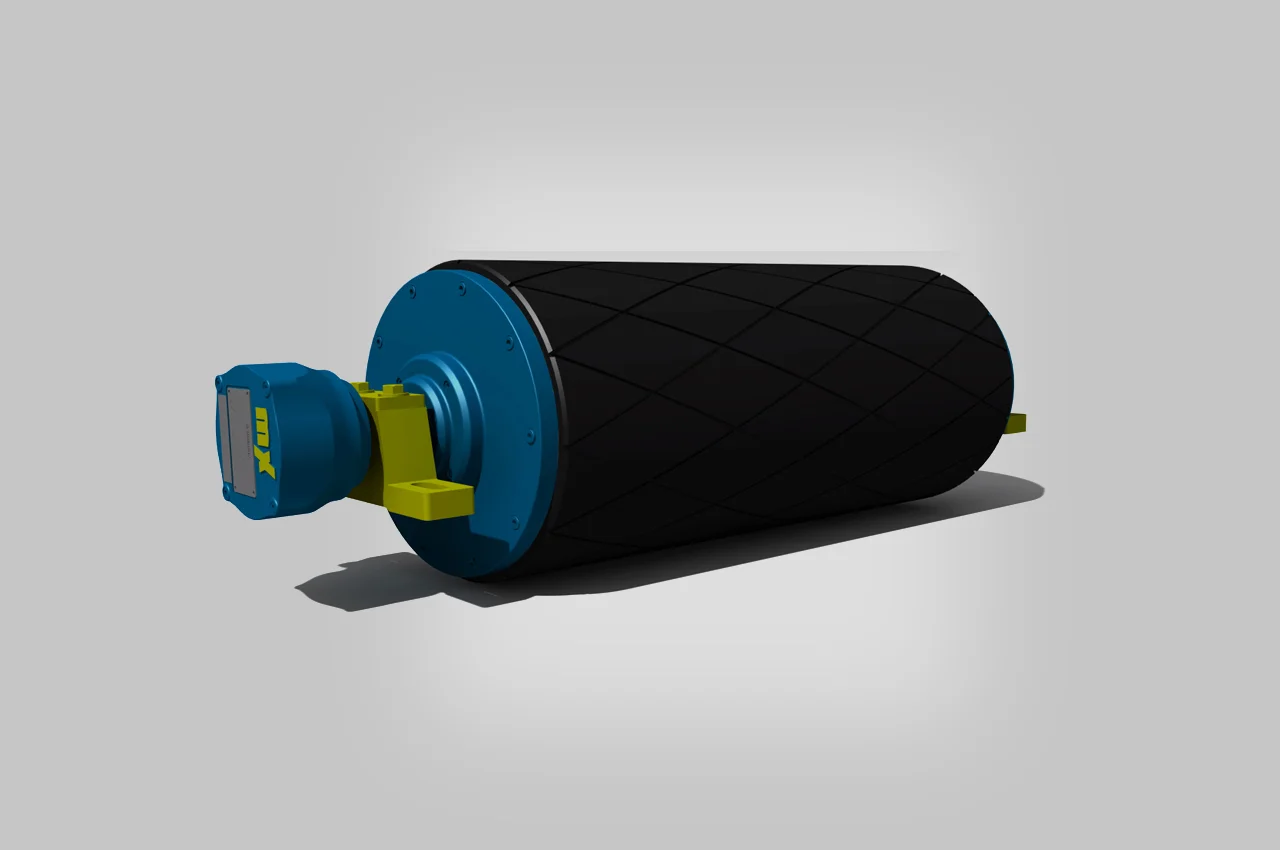

Scan X series

Drum Motors ED series